membrane house

Nội dung bài viết

In recent years, the model of shrimp farming in the membrane has been applied in many localities across the country because of high income and control of environmental pollution.

Benefit

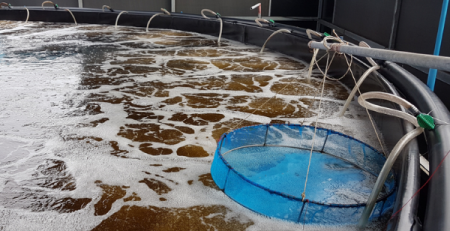

In fact, in the past time, shrimp farming in the film house helps to actively control the living environment for shrimps, controlling the temperature in the best way, this is a very important stage in shrimp farming. Because normally, when the rainfall is heavy or the sun is hot, the temperature in the pond will change quickly, affecting the health of shrimp. Moreover, indoor shrimp farming does not require water exchange, water resources can be utilized to stock shrimp in the next crop. Therefore, people will be proactive in treating wastewater in shrimp farming environment, a long-standing pressing issue without remedial solutions. In addition, when using membrane houses, farmed shrimp will avoid insect infestation, which can limit the spread of pathogens from outside. Therefore, this is considered an effective solution to help create clean, quality and safe shrimp products, meeting many strict standards.

Advantages

The galvanized steel frame makes the frame long-time.

Easy to assemble, can move to any location.

Overall solution

Each module of a shrimp farm has a width of about 24 m; length from 36 to 50 m depending on the farmers’ use; rainwater will be completely and completely blocked by the two sides of the membrane. The house is composed of the following main materials: Galvanized steel of good grade or anti-salt coating; 5-layer European technology plastic film or thick Israeli greenhouse film; Insect screen mesh around. Each module is interlaced with green trees to help reduce the temperature caused by solar radiation.

Construction

Determine the size of each module; identifying nails;

Excavation and construction of column foundation;

Execution of items of rainwater drainage ditches and tarpaulins with proper technical foundation and gas pond bottom drainage;

Installing roof frames and covers;

Installing hot air drainage system;

Install oxygen filling system.

Operate

First, clean the whole house;

Condensate water into ponds, adjust the concentration of salt, pH, dissolved oxygen.

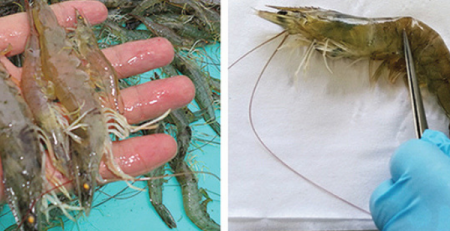

Drop sample shrimp exploration;

Drop according to the recommended shrimp density depending on the breed and dissolved oxygen.

Request

Farmed shrimp in the membrane has many advantages such as easy control, shrimp growth is quite fast, especially commercial shrimp after the harvest is good and beautiful, so it is bought by export processing companies with high price compared to the market. school However, it is usually kept in a high-density housing, so the system of fan and oxygen bottoms must operate continuously 24/24 hours. Inside the membrane house, the ponds are lined with bottom, the salt water is treated by a settling pond and then put into the pond. Accordingly, once every 5 days, microorganisms must be transplanted once and weekly to check the growth of shrimps to adjust the amount of food and water environment in time.

Maintenance

During the rearing process, it is necessary to maintain the brightness of the film through periodic cleaning to help the system become antibacterial;

Regularly check the hot air drainage stage of the fan system;

Periodic inspection of double-layer doors and disinfectants.

Source: Vietnam Fisheries Magazine