Improve the performance of shrimp farming aerators

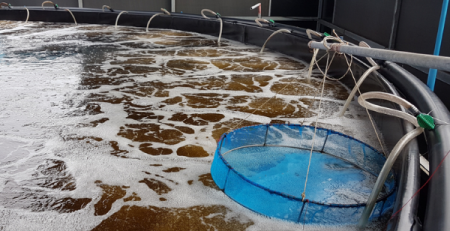

According to industry aerator, Gardner Denver, to help shrimp and fish farmers reduce operating costs, improve efficiency and increase productivity in using air blowers and compressors on their farms. Some work needs to be done to increase the efficiency of shrimp aerators.

Pneumatic and air blowing technology is used in the aquaculture industry

The size, depth and shape of the pond are important factors in determining which aeration system will work best. Air compressor – is a pump that creates compressed air that is brought to the bottom of the pond. Compressors are usually placed on the shore, near the pond, but they can also be placed ten meters away from the pond.

Nội dung bài viết

Increased performance for aeration compressor for shrimp and fish farming

Environmental conditions

Air temperature increase of 50C will reduce the efficiency of your air compressor by 2%. The compressor runs more efficiently if the inlet air is not too hot, so a simple method of opening the vents will effectively remove 2% of the loss.

Leakage

Compressed air leaks are the leading cause of energy loss in industrial aeration systems, wasting 20 to 30% of compressor production. The loss of air is proportional to the size of the leak and the pressure supplied in the system. However, even small leaks can be very expensive, because it leaks a large amount of air over time if not handled. Regularly check the aeration system and use good airways to avoid leakage.

Reduce the minimum pressure

The energy used by your air compressor is affected by many different factors, one of the most important is their operating pressure. Therefore, to reduce the energy of the equipment, it is necessary to ensure the minimum pressure drop in the pipeline network. As shortening the pipe gap and smooth pipe bends are two of the many examples involved in installation that will ensure energy savings. Not only does the problem set but also the aerator components also have an effect on pressure drop.

For example, if the filter is blocked, if it is not replaced, it will reduce the machine pressure and will generate additional energy consumption to compensate for these losses. Therefore, to ensure energy saving, it is necessary to check the filter blockage as well as the air diffuser.

Lower noise

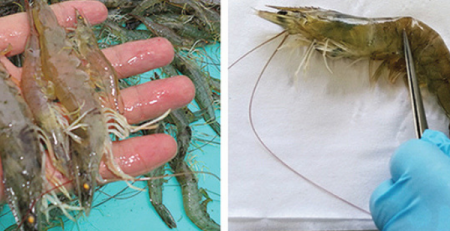

The high noise generated by the blower is often related to the large blower or the wrong type of blower application. It is very important for blowers to operate within reasonable range of best performance points (BEP). The air compressor’s noise reduction solutions contribute to reducing the environmental impact on shrimp, improving the welfare and productivity of animals because healthier shrimp feed more and gain weight faster. Shrimp health is not the only consideration, a quieter farm is also more comfortable for farmers due to improved working conditions.

IoT – Internet of Things

IoT-connected systems give farm owners the power to visualize ponds, ensuring operational efficiency. Any problems related to the aeration system will be immediately reported to help farmers know how to adjust and correct in time.

Lifetime use

Review the total life cycle cost of the aeration system. Buying prices alone may seem positive, but future costs may far exceed the initial investment. A low-quality blowers in the long run will cost you more in terms of production time and output lost due to failure and loss of efficiency. Usually low quality machines suffer from frequently clogged filters, require more maintenance and have a much higher incident rate. Higher wear rates in machinery lead to reduced performance much earlier than the expected life of the device.

Equipment maintenance

Regular maintenance and maintenance services are essential to ensure your device operates reliably and efficiently. Therefore, solutions that are easier to maintain or require less maintenance are better. Suppliers can service your entire air system, including blowers, pumps and compressors that will ensure all maintenance checks are performed in one visit. Minimize disruption and ensure necessary maintenance is carried out in a timely and efficient manner.

Use main spare parts

Always use genuine parts. By using genuine parts, you are using components manufactured according to specifications that do not match the parts of the machine that could result in a problem at a later date. Genuine components fit the machine and have passed rigorous durability tests and provide the best protection for your investments.

Hopefully, the above information will be useful for everyone to ensure the efficiency of aeration air compressor in shrimp and fish ponds.

According to Vietfish Magazine