Evaluate the characteristics of the pond under the canvas

HDPE can easily be washed after each crop

Advantages

HDPE can help farmers to reuse ponds or ponds that have been contaminated with alum or contaminated soil, saving costs and time. Besides, there are many advantages, in particular:

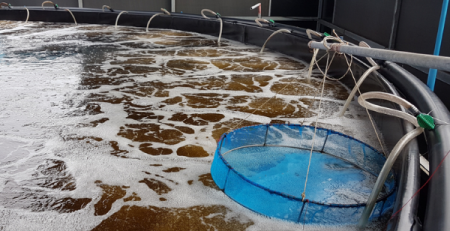

Waste collection: In ponds, waste is collected in the middle of the pond, so it is easy to remove, easy to control pond bottom, minimizing outbreaks of harmful bacteria and toxic gases. The risk of damage is low as the pond is designed with safe and secure siphon system. During the rearing process, ponds are not polluted by harmful chemicals stored in the soil, because the soil is isolated from the bottom.

Water quality assurance: With ponds and ponds, water quality in ponds is difficult to control because they are always affected by the surrounding environment such as toxic water in soil, water contaminated by alum from pond and pond. However, in the pond under the canvas HDPE completely isolate water in the pond with external water, preventing the intrusion of bacteria and harmful organisms to shrimp, water quality is maintained stable.

Control of environmental factors: Water retention capacity of the pond under the canvas HDPE is very good, helping farmers reduce costs in the stage of water supply for shrimp ponds from which to manage water resources, control the parameters in ponds Aquaculture such as pH, alkalinity, oxygen, salinity to take timely remedial measures in case of environmental incidents.

Due to the black color of the tarpaulin, it absorbs more heat and is usually disinfected by sun exposure within 3 to 4 days. If it is necessary to use chemicals, the amount of chemicals is much less than that of earthen ponds and then easily washed away.

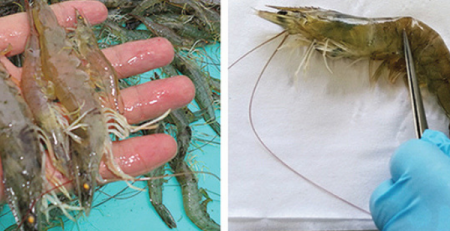

Finally, according to Bray and the research team in 2001, they successfully farmed white leg shrimps on former White Spot Disease (WSSV) farms in ponds using HDPE tarpaulins. Survival and development in these ponds was up to 80% while only 9% of shrimp survived in earthen ponds. In addition, stocking density in ponds was higher than that in ponds by more than 30 times.

Defect

Most importantly, the initial investment cost for other ponds is high.

When using pond linings, a certain amount of labor and manual equipment is needed to properly clean and prepare the ponds before proceeding to the next production cycle.

Water coloring or phytoplankton formation in ponds before stocking is much more difficult. Micro-organisms in ponds are less abundant than earth ponds, so natural yields are also lower than ponds.

The increased rate of phytoplankton will lead to problems associated with depletion of oxygenated aerobic mechanics than may be required in pond lakes than in non-primer ponds, particularly in the second half of the breeding period.

Note

For the use of ponds in HDPE for commercial shrimp farming using Biofloc technology, farmers should note: The characteristics of this system is relatively small ponds (0.5 – 1.5 ha), lined with HDPE tarpaulin (usually 0.75-1 mm HDPE), strong airflow to maintain feed / suspended solids in the pond; Water fans must be kept in place to prevent accumulation of mud and the position of the fan should be changed frequently to avoid the formation of harmful anaerobic gases. The suspended solids content of 15 ml / l was maintained by adding cereal flour (18% protein) and molasses, the added assurance ratio was greater than 15: 1 (C: N); When the shrimp reaches about 10 tons / ha, it should be sucked in the center of ponds.

High quality and prestige HDPE tarpaulins must be manufactured from virgin resin, recycled and recycled for at least 5 years. HDPE treads must be certified to contain feed water (NSF 61 & AS / NZS 4020) and contain no additives, chemicals that can affect water quality and harm animals. HDPE tarpaulins with a thickness of 0.75 mm or more must meet the GRI-GM13 standard of the Geotechnical Research Institute.

Thai Thuan (General)

Contom.vn