Prepare shrimp ponds to prevent diseases

Nội dung bài viết

Well prepared ponds to follow appropriate steps to ensure the proper conditions for the next production cycle are extremely important in raising and preventing shrimp diseases.

Pond improvement is a step to prepare suitable conditions for the next crop, which plays an important role in helping farmers actively handle problems occurring in the farming process while saving production and operation costs and contribute to limiting disease for farmed shrimp.

After harvesting shrimps, ponds need to perform many different processing steps to prepare for the next culture cycle. Improving the pond to avoid the spread of pathogens from one crop to another and help ensure environmental factors suitable for shrimp farming. If the pond improvement process is not good, pond bottom is degraded, the amount of sludge accumulated will cause the shrimp to grow slowly and increase the concentration of toxic gas in the pond. The quality of soil and water reduces shrimp diseases.

Pond drying, soil preparation, lime application

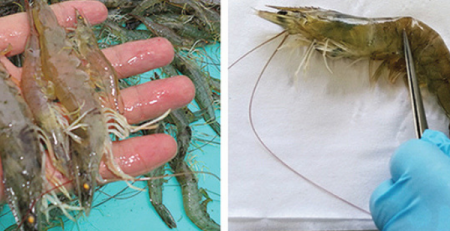

The accumulation of clay particles is eroded from soil and organic matter derived from dead plankton, uneaten food, and shrimp manure. To clean the pond bottom after each crop, it can be done by using a high pressure hydraulic pump with suction or pushing the waste out of the pond when the pond bottom is wet or using the excavator after the bottom is dry.

Removal of sediment after each crop is necessary. Harvested ponds are usually dried in the sun for two weeks or more. This step helps to reduce the moisture content of the soil to kill most organisms (including disease-causing organisms) left in the pond after drainage. The use of harrows aims to break down the soil mass, increase the soil’s exposure to air and increase the drying rate. Tractors can also be used for this purpose, but land plowing machines are not effective. Some ponds have rough surfaces with subsidence that keeps the water long after the rest of the bottom is dry. Some ponds cannot dry completely due to the intrusion of groundwater from nearby ponds or canals. Completely drying the pond bottom is impossible, especially during the rainy season. Farmers can use lime or hydrated lime applied to the bottom of the pond with a minimum dose of 3,000 kg / ha (300 g / m2) of lime or 4,000 kg / ha (400 g / m2) of hydrated lime to increase Soil pH to destroy unwanted organisms. Pond drying and lime treatment for non-dry bottom areas is the best process for pond treatment and renovation.

Calcium hypochlorite Ca (ClO) ₂ – Chlorine disinfectant, is a mixture of lime and calcium chloride that can also be applied on wet areas for sterilization purposes in quantities of 100-200 g / m2. Copper sulfate, formalin and potassium permanganate (potassium permanganate) have also been used to disinfect soil, but they are not as effective as lime or chlorine. Pond bottoms with soil pH below 7 should be adjusted to increase pH. Can use lime or hydrated lime to neutralize the acidity of the soil. If the pond is completely dry and no lime is used to disinfect it, agricultural limestone can be used to neutralize the acidity of the soil. Agricultural limestone should be spread evenly on the pond bottom while the soil is still moist.

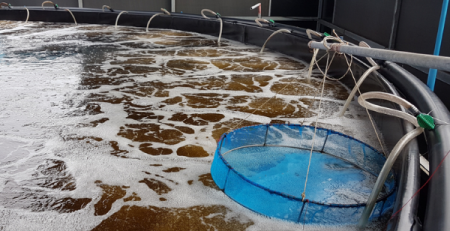

Water supply, sterilization

Feed water into the pond is usually through good filter bags or sieves to remove unwanted organisms. Although the filtration process will reduce the amount of trash fish entering the pond, it cannot prevent the entry of other pathogenic organisms. The most effective way to prevent the entry of pathogenic organisms is to disinfect through water supply. Disinfectants can be applied to water stored in settling ponds or carried out directly in ponds. A variety of disinfectants such as calcium hypochlorite, chloramine T, potassium permanganate, copper sulfate, hydrogen peroxide, iodine compounds, benzalkonium chloride and glutaraldehyd are used. The most effective is calcium hydochlorite at a concentration of 20-30 mg / L.

Causing color and stocking

Shrimp seed cannot be released until the toxic effect of the disinfectant has dissipated, which usually only takes 3-5 days. However, after the process of pond bottom is usually dried, lime is thrown into the bottom and the water is disinfected then the pond usually has clear water. Shrimp seed can use commercial feed, but they benefit greatly from natural food for a few weeks after stocking. Ponds should be colored to encourage the growth of phytoplankton, zooplankton and benthos before stocking. Fertilization with urea and superphosphate or other commercial fertilizers can be used to promote phytoplankton growth. However, the use of a combination of organic fertilizer and commercial fertilizer. will lead to a rapid increase in zooplankton and benthic organisms rather than just using commercial fertilizers. And a better way is to apply soy flour, shrimp feed, rice bran or some other high quality organic matter. Appropriate ratio is 6-8 kg nitrogen (12-18 kg / ha urea), 1 – 2 kg of phosphorus (5-10 kg / ha superphosphate) and about 100-200 kg / ha of high quality organic fertilizer. The beatings should be repeated if the algae do not develop within 4 – 5 days. Sometimes it can take up to two weeks to get a beautiful colored pond. The coloration may have to be continued for 2-3 weeks to maintain the algae growth, but once the feeding rate reaches 20-30 kg / ha / day, it is not necessary to induce coloration by having enough nutrients due to leftovers, feces and shrimp excretion.

Source: contom.vn